At Herc’s Truck Service, we specialize in providing comprehensive air brake services for commercial trucks. As a critical component of a truck’s braking system, air brakes require regular maintenance and attention to ensure safe and reliable operation. With our experienced technicians and state-of-the-art facilities, we offer top-quality air brake services to keep your fleet operating at its best.

Air brakes work differently than traditional hydraulic brakes found in most passenger vehicles. Here’s a simplified explanation of how air brakes operate:

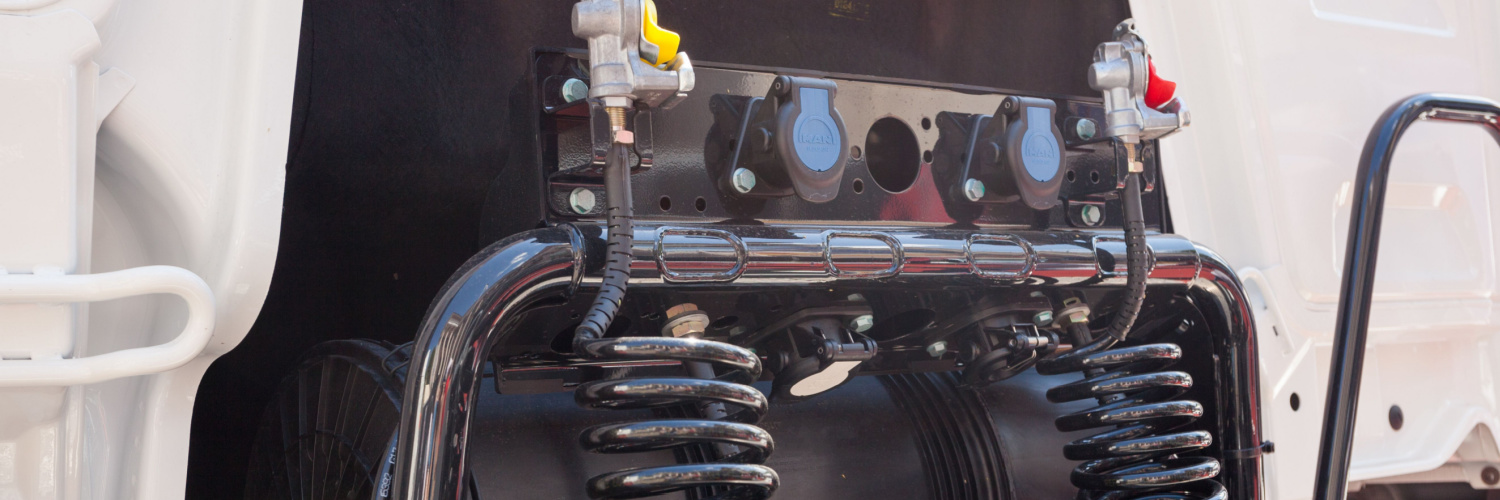

Compressed Air Generation: Air brakes use compressed air as a power source. An air compressor, driven by the truck’s engine, pressurizes air from the atmosphere and stores it in air tanks.

Air Brake System Components: The air brake system consists of several key components, including the air compressor, air tanks, air dryer, brake valves, brake chambers, slack adjusters, and brake shoes or pads.

Brake Application: When the driver applies pressure to the brake pedal, it activates the brake valves, allowing compressed air to flow from the air tanks into the brake chambers.

Brake Chambers and Slack Adjusters: The air pressure from the brake chambers pushes against the brake shoes or pads, creating friction against the brake drums or discs. Slack adjusters ensure the proper clearance between the brake shoes or pads and the drums or discs.

Brake Release: When the driver releases the brake pedal, air is released from the brake chambers, allowing the brake shoes or pads to move away from the drums or discs, and the truck to resume normal operation.

The main difference between normal brakes (hydraulic brakes) and air brakes lies in the power source used to generate braking force:

Power Source: Hydraulic brakes use hydraulic fluid to transmit force from the brake pedal to the brake calipers or wheel cylinders, which then apply pressure on the brake pads or shoes against the brake rotors or drums. In contrast, air brakes use compressed air to generate the necessary braking force.

Application and Release: Hydraulic brakes rely on the direct force applied by the driver’s foot on the brake pedal. When the pedal is pressed, hydraulic fluid pressure increases, leading to brake application. Releasing the pedal reduces hydraulic pressure, allowing the brakes to release. On the other hand, air brakes use air pressure to apply and release the brakes, controlled by the driver through the brake pedal and various valves.

Heavy-Duty Applications: Air brakes are commonly found in heavy-duty vehicles, such as commercial trucks and buses, due to their ability to handle higher braking demands. The compressed air system provides consistent braking performance even in challenging conditions, making them ideal for larger and heavier vehicles.

Although air brake systems are designed to be highly reliable, it’s essential for drivers to know what to do in case of a brake failure situation. Here are the recommended steps to take if air brakes fail:

Stay Calm: In a brake failure situation, it’s crucial to remain calm and focused. Panicking can lead to poor decision-making and potentially hazardous situations.

Downshift and Engine Brake: Downshift to lower gears to utilize the engine’s braking power, which can help slow down the vehicle. Many commercial trucks are equipped with engine braking systems, commonly known as “Jake brakes” or “compression brakes.” Engaging these systems can provide additional braking assistance.

Use Emergency Brakes: Commercial trucks are typically equipped with a separate emergency or parking brake system. Apply the emergency brake cautiously, as it may not provide the same level of stopping power as the primary air brake system.

Signal and Communicate: Use hazard lights, horn, and any available communication devices to alert other drivers and pedestrians about the brake failure situation. Communicate with nearby vehicles and emergency services to ensure their awareness and assistance if needed.

Find a Safe Area: Attempt to bring the vehicle to a controlled stop in a safe location, such as a designated pull-off area or an open space away from traffic. Avoid sudden maneuvers or abrupt stops that could cause further hazards.

Seek Professional Assistance: Once the vehicle is safely stopped, contact a reliable truck service provider like Herc’s Truck Service for immediate assistance. Our expert technicians can diagnose the issue, repair the air brake system, and ensure that your truck is back on the road safely.

It’s important to note that regular maintenance and inspections can help prevent air brake failures. By following scheduled maintenance programs and promptly addressing any identified issues, you can reduce the risk of brake system malfunctions.

At Herc’s Truck Service, we prioritize the safety and performance of your commercial truck fleet. Our experienced technicians are well-versed in air brake systems and provide comprehensive air brake services, including inspection, maintenance, repair, and adjustment. With our commitment to quality and customer satisfaction, you can rely on us to keep your trucks’ air brake systems in optimal condition. Contact us today to schedule an appointment or learn more about our air brake services.